Why Component Precision Matters in Pharma Equipment

At MJ Enterprise in pharma manufacturing, the quality of components directly influences process efficiency and patient safety. Even the slightest deviation in component tolerances can cause:

- Contamination risks from poor surface finishes or incompatible materials

- Measurement inaccuracies leading to under/overdosing

- Downtime and breakdowns from wear or improper fitting

Tailored Component Solutions for Key Pharma Equipment

Blending Equipment Components

Mixing blades and drive shafts crafted to tight specs ensure homogeneous blending and minimize material cross-contamination, essential for batch consistency.

Capsule Equipment Parts

We machine dosing mechanisms and precision nozzles to maintain accurate fill weights and meet pharmaceutical-grade material requirements.

Centrifuge & Separation Components

Our custom rotors and containment vessels offer high-speed stability and material purity, even under extreme mechanical stress

Coating Machine Components

From spray nozzles to mixing arms, our parts enable uniform coating and contribute to machine longevity, especially under abrasive use.

Filling Equipment Components

Precision pistons, nozzles, and valve assemblies support accurate and sanitary filling for both liquid and powder formulations.

Milling Machine Parts

With high-performance blades and durable screens, we deliver components built for particle size consistency and wear resistance.Tablet Press Components

Our punches, dies, and rollers ensure uniform compression and dosage accuracy, critical for therapeutic compliance and brand trust.Materials That Meet Pharmaceutical Standards

We work with materials that are certified and compliant for pharma environments, including:

- SS 316L for superior corrosion resistance and cleanability

- High-purity alloys for strength and inertness

- FDA-compliant engineering plastics for special applications

Innovation and Adaptability in a Regulated Industry

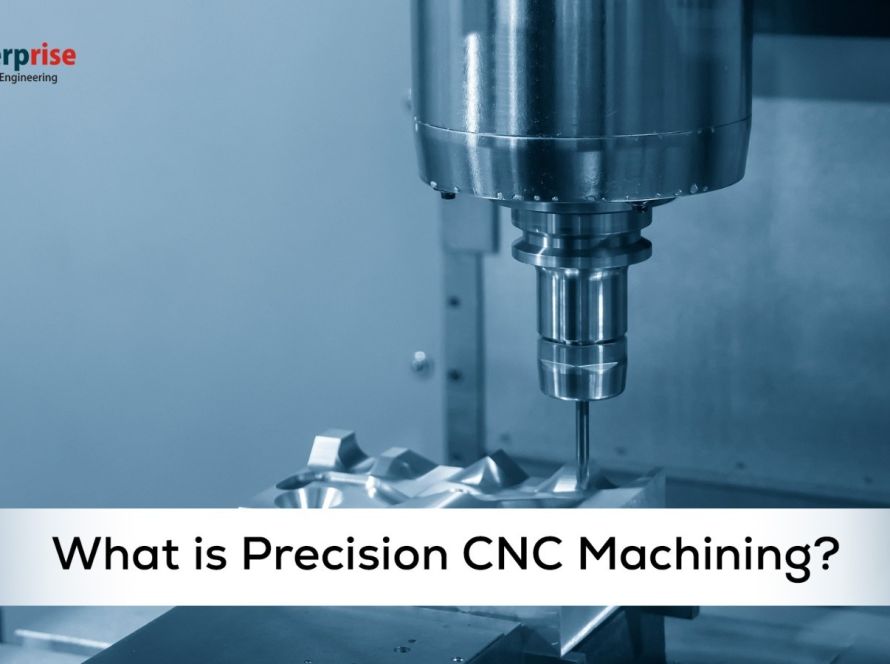

With investments in CNC machining, we continuously enhance our capabilities to:

- Deliver highly customized components with fast turnaround

- Adapt to new drug formulations and machinery requirements

- Scale production as client operations grow

Conclusion

At MJ Enterprise, we blend pharmaceutical expertise with CNC machining precision to craft components that exceed performance and compliance standards.

Elevate your pharma equipment today — partner with us for reliable, high-quality CNC solutions.