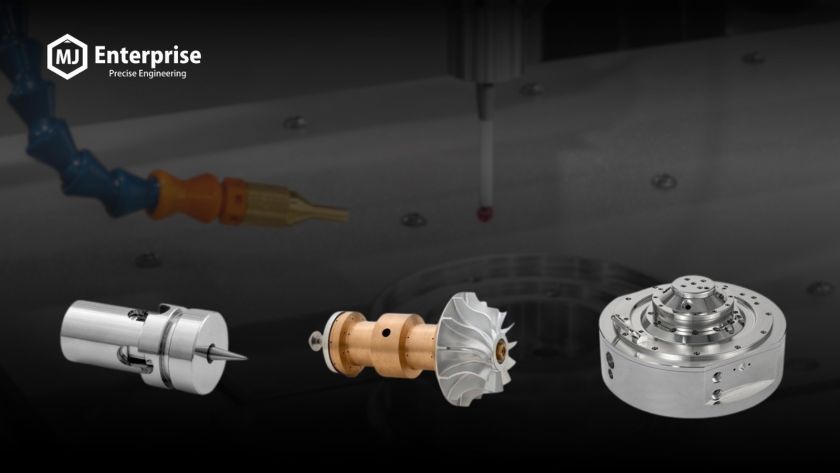

Modern manufacturing increasingly depends on complex systems built from multiple precision-machined components. While producing individual parts with high accuracy is essential, achieving actual product performance requires these components to be correctly assembled and integrated into functional systems. This is where assembly and sub-assembly of machined parts play a crucial role in ensuring quality, reliability, and…